About The Company

Our History

Ningbo Jinggang Machinery Co., Ltd. is a professional metal group company, we have 15 years of experience, specializing in customizing various machinery parts, after years of development, we have become the main iron, steel and aluminum casting component solutions provider in Ningbo, China. With a global network and a strong local presence in major markets, Jinggang is ready to provide customers with the entire component supply chain from engineering to casting, machining and surface treatment.

Our performance is based on knowledge of our customers' business and excellence in engineering, casting and machining services, Jinggang values and sustainability.

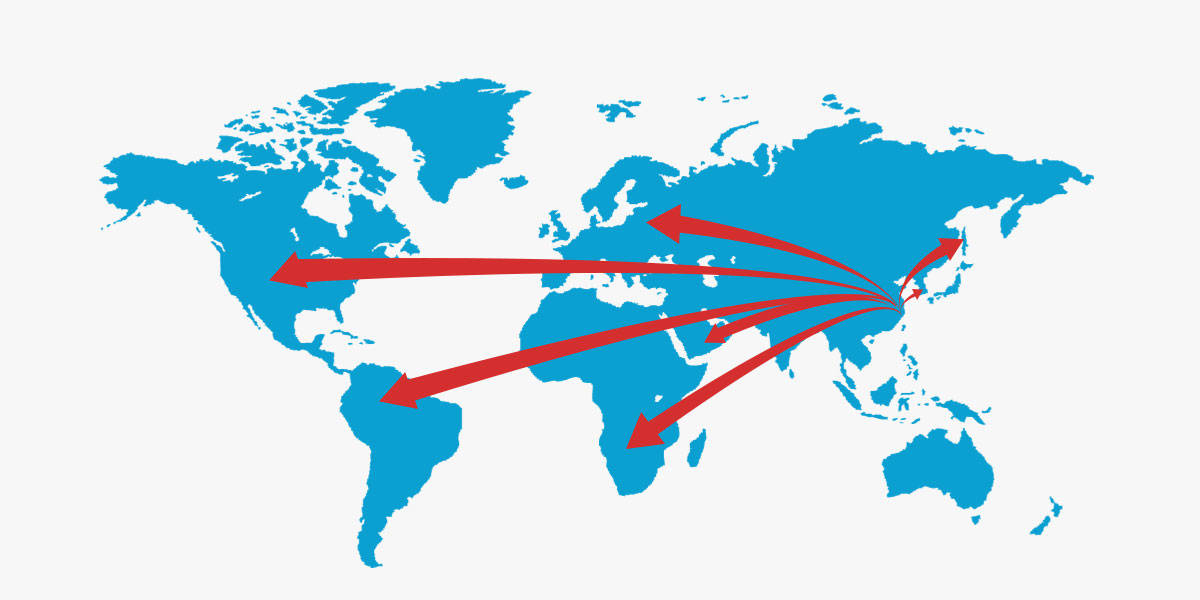

Our products are designed to meet customer specifications and undergo rigorous quality control testing. Our products are typically used in water systems, industrial machinery, vehicles and ships, construction, mining and agriculture. More than 95% of our products are exported to the United States, Italy, Germany, the Netherlands, Canada, France, Belgium and other Western countries.

We have access to all required professional software, including (but not limited to) Auto-CAD, Pro/E, UG, CATIA, SOLIDWORKS, ProCAST, and CAE.

Jinggang also provides a full range of services from design and integrated manufacturing operations to strict quality control throughout the manufacturing process. We have established a comprehensive quality control system so that all products comply with ISO9001:2008 regulations. Our quality control runs through every step of the production process.

Our Factory

Jinggang factory is located in the suburbs of Ningbo, close to Ningbo Port, with very convenient transportation. The factory covers an area of 4,000 square meters and has dozens of employees. Depending on market conditions, our annual sales are between US$2 million and US$4 million.

Since the establishment of the factory, we have been committed to customizing various mechanical parts according to customer drawings. Our business covers stamping parts, sand casting parts, machining parts, welding parts and assembling parts.

Our factory has four main workshops and a laboratory, including stamping workshop, machining workshop, welding workshop and assembly workshop. These workshops have 20 stamping machines, 40 CNC machine tools and multiple welding equipment. The laboratory is equipped with some testing equipment, including CMM, projector, universal strength testing machine and hardness tester.

We always follow the principle that quality is the life of an enterprise, so we have established a strict quality control system to make our products comply with the regulations of ISO 9001. We have also passed TS 16949 certification.

Due to our competitive prices and excellent quality, our products have been recognized by customers all over the world and are mainly exported to North America, Europe, the Middle East, Southeast Asia and Africa.

Product Application

water systems, industrial machinery, vehicles and ships, construction, mining, and agriculture.

Production Equipment

20 sets of punching machines, 40 sets of CNC machines and several sets of welding equipment.

Production Market

North America, Europe, Middle east, Southeast Asia and Africa.

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Dansk

Dansk  Suomi

Suomi  العربية

العربية  ελληνικά

ελληνικά  český

český