How do Medical Machinery Parts decide clinical reliability today?

2025-12-10

I learned the hard way that hospitals don’t buy features—they buy outcomes. When I audit a supplier or walk a production line, everything comes back to the quality of the assemblies we place in the field. The quiet backbone is Medical Machinery Parts, and the partner that keeps showing up in my notes is Jinggang, because their process discipline maps to the way procurement teams, engineers, and regulatory staff actually work. This is my field guide to selecting and scaling Medical Machinery Parts without drama, from first RFQ to post-market life.

Why do buyers still struggle to compare suppliers for complex parts?

Specs look similar on paper, yet risk hides in the gaps—ambiguous tolerances, finish definitions that don’t translate, and validation steps that arrive too late. I now start every project with three anchors: measurable fit-for-sterilization, traceability that survives audits, and a DFM loop that reduces burrs, corners, and dead legs before quoting. When these are explicit, the discussion around Medical Machinery Parts becomes objective instead of hopeful.

Which materials, finishes, and sterility paths actually balance performance and cost?

- Metals: 316L/317L stainless for corrosion resistance and passivation; Ti-6Al-4V ELI when weight and biocompatibility trump cost.

- Polymers: PEEK or PPSU for repeated steam cycles; PC for transparent housings; PTFE for low-friction interfaces.

- Finishes: Electropolish and controlled Ra for fluid paths; bead-blast or micro-polish for grip and cleanability; passivation for stainless consistency.

- Sterilization: Autoclave, EO, or gamma—material choice must be tied to the real cycle count and packaging you intend to use.

I treat each of these as levers that I can tune against risk, then lock them with incoming, in-process, and final checks. Done right, this keeps Medical Machinery Parts stable across lots and sites.

What tolerances matter most once devices leave engineering and hit the clinic?

- Interfaces over isolates: I tighten dimensions where parts meet gaskets, bearings, optics, or sensors, not on vanity features.

- Thermal reality: I ask for CTE-aware stack-ups that model autoclave excursions and cold storage, not just room-temp drawings.

- Surface function: For sliding or sealing, I specify roughness and lay direction alongside size; otherwise seals scrape, not seat.

This sharpened focus prevents chasing microns no one needs while protecting the interfaces that define how Medical Machinery Parts behave under load, vibration, and sterilization stress.

Can I use a simple matrix to match parts to materials, finishes, and checks?

I keep a living table that links common subcomponents to practical choices. It’s not a rulebook—it’s a conversation starter that accelerates quoting, FMEA, and validation for Medical Machinery Parts.

| Part type | Recommended material | Sterilization path | Critical tolerance | Typical finish |

|---|---|---|---|---|

| Pump rotor / impeller | 316L SS or Ti-6Al-4V ELI | Autoclave; EO fallback | ±0.01–0.02 mm on OD, concentricity <0.02 mm | Electropolish, Ra ≤0.4 μm |

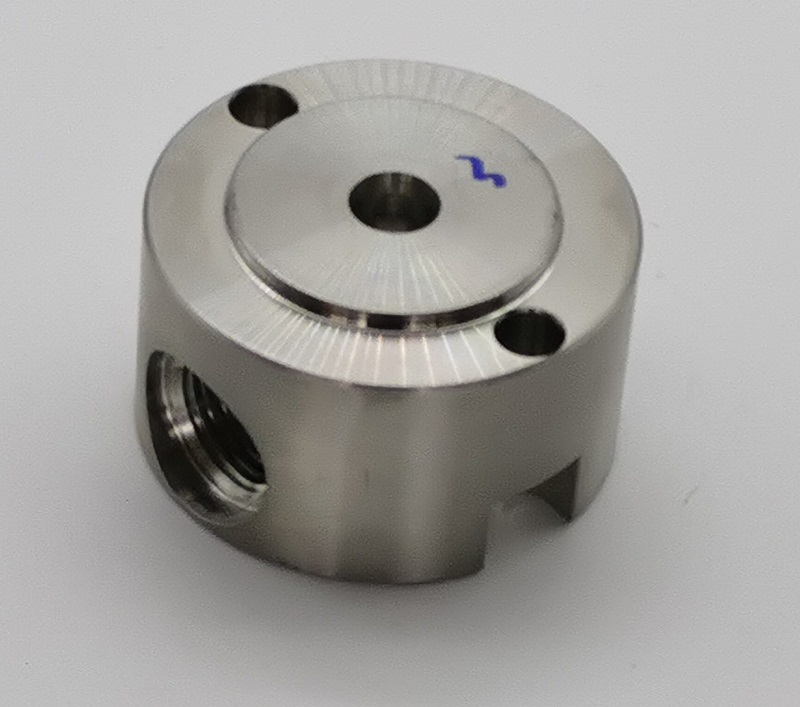

| Valve body / fluid block | 316L SS or PEEK insert | Autoclave / gamma (PEEK) | Flatness <0.03 mm; port position ±0.02 mm | Passivated; deburr Class A |

| Sensor housing | PPSU or PC (clear) | Steam (limited cycles) or EO | Window parallelism <0.05 mm | Micro-polish, Ra ≤0.8 μm |

| Drive shaft / gearbox pinion | 17-4PH or 440C SS | Autoclave compatible oils removal | Runout <0.01 mm; hardness verified | Ground finish, Ra ≤0.2 μm |

| Manifold with UDI mark | 316L SS | Any; marking validated | Channel size ±0.02 mm | Electropolish; laser UDI contrast |

| Enclosure / handle | PPSU / PC-ABS blend | EO / limited steam | Assembly fit ±0.1 mm | Texture for grip; cleanable edges |

How do I read a quote and predict total cost before the first PO?

- Ask for process flowcharts—CNC, deburr, passivation, electropolish, clean, package—so invisible steps don’t become surprise surcharges.

- Request capability data on pilot runs (Cp/Cpk on CTQs), not just inspection snapshots.

- Model tool life and changeover time if mix is high; this is where lead time creeps.

When a supplier like Jinggang shows their flow and gage plan without prompting, I can forecast the landed cost of Medical Machinery Parts with fewer unknowns.

What proof convinces auditors that my supply chain is under control?

I look for ISO 13485 discipline, device-level thinking, and traceable data: serialized lots, calibrated CMM programs, IQ/OQ/PQ evidence tied to real parts, and cleanroom handling where needed. PPAP-style packages help in regulated environments, but I value living control plans even more. With this foundation, the validation story for Medical Machinery Parts is defensible and repeatable across geographies.

Where does Jinggang actually change the outcome on the production floor?

What I notice is a bias toward prevention: early DFM on burr-prone edges; fixture strategies that protect sealing faces; finish verification with Ra and lay documented; and packaging that preserves finish through transport and sterilization. That’s where slippage usually begins. When these controls are routine, ramping volumes or introducing a variant doesn’t destabilize Medical Machinery Parts downstream.

Which KPIs should I track after onboarding a new partner?

- First-pass yield and scrap by defect code—kept weekly, not quarterly.

- Delivery promise adherence and change-order frequency.

- CTQ capability stability after tool maintenance or revision changes.

- Sterilization cycle hold-up time caused by packaging or residue issues.

If these stay green over three consecutive lots, I know my Medical Machinery Parts program is resilient enough to scale.

How should we move from RFQ to validated supply without losing speed?

- Start with a pilot bundle of 3–5 representative SKUs to qualify the extremes of your design space.

- Lock metrology (gages, CMM programs, sampling plans) before the first pre-production run.

- Co-develop a cleaning and packaging spec that mirrors the real sterilization path.

- Use a rolling PPAP/FAI schedule so learnings from the first article flow into the next.

This staged path has saved me months while preserving validation integrity for Medical Machinery Parts.

Would you like a clear next step that respects your timeline?

If you want a fast, evidence-driven review of your current drawings, send the two most failure-prone SKUs and your sterilization method. I’ll respond with a material-finish-tolerance map and a risk-ranked control plan that you can use with any qualified shop. If you’d like to see how Jinggang would approach your mix, we can mirror the same review and provide a quote with flow, gaging, and packaging built in. Ready to simplify procurement for Medical Machinery Parts? Please contact us with your RFQ, drawings, and target volumes—tell me your deadline and we’ll align the validation plan around it.

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Dansk

Dansk  Suomi

Suomi  العربية

العربية  ελληνικά

ελληνικά  český

český