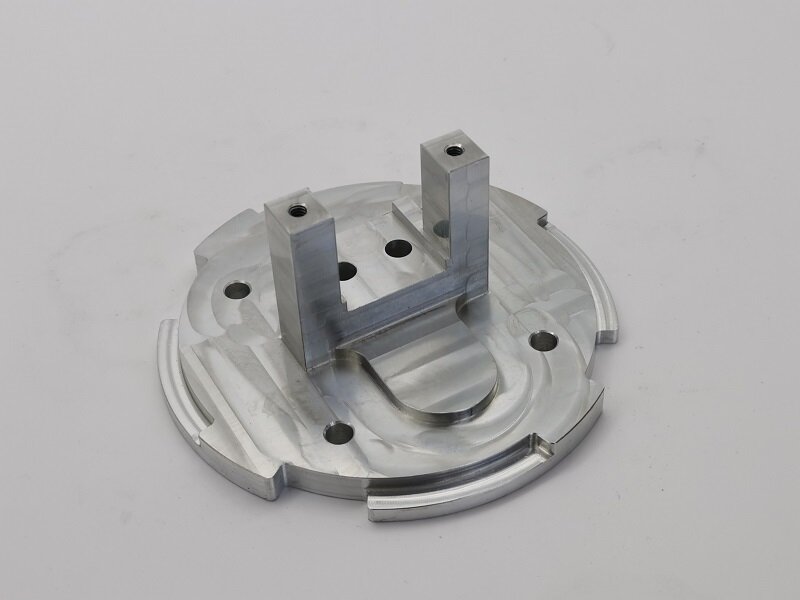

China Die Casting Part Manufacturer, Supplier, Factory

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Die Casting Part,Aluminium Die Casting Parts, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, don't hesitate to contact us.

Die Casting Part, During in 11 years, We now have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

Hot Products

Forging Intake Exhaust Engine Valve

The material of the forging Intake Exhaust Engine Valve is composed of alloy steel, which is processed by forging process, machining process and grinding process. Products are mainly used in diesel engine spare parts. forging Intake Exhaust Engine Valve is mainly customized according to the drawing, no inventory. Capacity can be adjusted according to customer needs.Stamping Metal Pulley

The material of the stamping Metal Pulley is ordinary carbon steel, stamping processing, surface galvanized rust prevention treatment. Each batch of stamping Metal Pulleys can provide mechanical properties report, material composition report, size report. This part is mainly used in the field of construction machinery. We can provide customized services according to customer needs, and also adjust our production capacity according to actual needs.CNC Machining High Precision Shaft

The material of CNC machining high Precision Shaft is alloy steel, which is processed by metal sheet. Each batch of CNC machining high Precision Shaft can provide mechanical properties report, material composition report, size report. This part is mainly used in civil machinery and construction machinery fields. We can provide customized services according to customer needs, and also adjust our production capacity according to actual needs.CNC Machining cooling jacket welding assembly part

The CNC Machining cooling jacket welding assembly part is a highly demanding assembly that is completed through the coordination of multiple processes. There are strict requirements for fine processing, welding and surface painting. The welded part is smooth without protrusions, cracks or leakage. A water pressure test is required after the welding is completed. The assembly and welding of the threaded nozzle and the pipe wall must be particularly precise and comply with the tolerance of the drawing; otherwise, it will interfere with the inner pipe assembly. The surface texture of the paint should be uniform, and the color fastness needs to meet the specified standard. Material: 304 stainless steel Paint brand: SHERWIN Packaging: Bubble wrap packaging to protect the paint from damage during transportation. Each batch of cooling jacket welding assembly part can provide mechanical properties report, material composition report, size report. The cooling jacket welding assembly part is mainly used in medical machinery fields. pls contact us and let our customers enjoy various manufacturing processes, flexible order volumes, and expert engineers service .Sand Casting Complex Pipe Connector

The sand casting complex pipe connector is mainly composed of alloy steel material and molded by sand casting. the sand casting complex pipe connectors have high mechanical strength requirements. Be able to provide material report, mechanical performance report, size report to meet the requirements. The product is mainly used in the core parts of general construction machinery equipment. We mainly provide customized processing business for customers, and the production capacity can be adjusted according to the needs of customers.CNC Machining Piston Housing

The material of CNC machining Piston housing is 17-4 PH stainless steel, high CNC machining process requirements, can not be any processing burrs and iron cutting residue. Surface passivation treatment. Each one needs to be wrapped in bubble wrap to protect the surface. Each batch of products can provide mechanical properties report, material composition report, size report. This CNC machining Piston housing is mainly used in the field of medical machinery. We can provide customized services according to customer needs, and also adjust our production capacity according to actual needs.

Related Search

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy

English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Dansk

Dansk  Suomi

Suomi  العربية

العربية  ελληνικά

ελληνικά  český

český